Medivent Grant

Medivent Grand

Anaesthesia Workstation

The Medivent Grand is an advanced Anaesthesia Gas delivery system. Its high-end features and modern ventilation capabilities make it versatile. It is quite compatible for Low Flow Anaesthesia. The Pressure control mode, FGF decoupling & compliance compensation give it a definite edge over other such devices. The mode of PRVC is very useful. The Hypoxic Guard, Oxygen Failure Protection, ORC and in-built FiO2 monitoring are some of the basic features.

Compensating for the internal compliance and the breath-to-breath correction work for accurate delivery of tidal volume. The effect of changing lung characteristics on ventilation has been minimized by using these advanced features.

Features

The assembly consists of five flow meter Tubes, two for oxygen, two for Nitrous oxide and one for Air. The tubes are illuminated by backlight for easy visibility. The Control knobs are colour coded and have different textures for easy identifications.

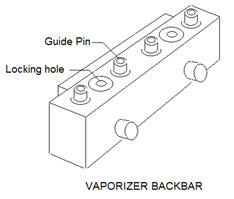

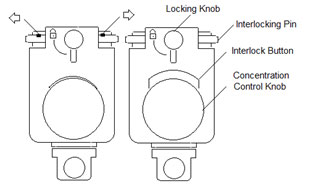

It consists of a vaporizer Back bar that can mount two Selectatecvaporizers side by side. The vaporizers have in-built interlocking system that ensures only one vaporizer to be operative at a time even if two vaporizers are present.

When a particular vaporizer is selected by pressing the Interlock Engage button, its interlock pin comes out to lock the other adjacent vaporizer.

The design has been made so that there is practically no wastage of fresh gas flow due to unwanted leaks at any stage of inspiratory-expiratory cycle. A part of fresh gas flow accumulating continuously in the system is released only when it crosses the thresh-hold limit. By using lower FGF, the amount of release can be reduced. In fact, the fresh gas flow can be reduced to the gas volume which the patient is absorbing and metabolizing while under anaesthesia. The unit is compatible for flow as low as 500ml per min.

The design has been made so that there is practically no wastage of fresh gas flow due to unwanted leaks at any stage of inspiratory-expiratory cycle. A part of fresh gas flow accumulating continuously in the system is released only when it crosses the thresh-hold limit. By using lower FGF, the amount of release can be reduced. In fact, the fresh gas flow can be reduced to the gas volume which the patient is absorbing and metabolizing while under anaesthesia. The unit is compatible for flow as low as 500ml per min.

The Benefits of low flow anaesthesia may be summarised as

-

Humidification in the range of 17 to 30 mgH2O/L and maintenance of minimal gas temperature of 280 C, required prolonged anaesthesia, is achieved easily.

-

Reduction of environmental pollution by volatile anaesthetics

-

50 to 70% reduction in cost for soda-lime, anaesthetic agents and oxygen/air

-

Lesser exposure for staff to anaesthesia gases in workplace.

It is a pneumatic device to regulate the flow of N2O corresponding to the flow of oxygen for maintaining the desired ratio between the gases. The device acts at where the gases are blended through the flowmeters.

It also acts as Nitro-lock facility and shuts flow of N2O if flow of oxygen falls below 1lpm. Additionally, it ensures FGF with at least 20% oxygen and checks against hypoxic fresh gas flow (FGF).

The chemical reaction in Soda-lime absorber is exothermic producing heat and water. However, the excessive accumulation of water in the absorber may hinder the flow of gas. To avoid such occurrences, a release valve has been incorporated in the absorber to drain out accumulated water automatically. The valve consistes of a float that normally blocks the outlet. The float gets lifted by the accumulated water and water is released.

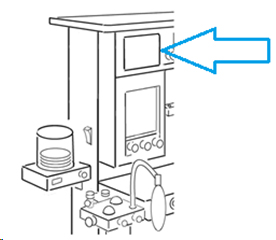

The ventilator is electronically controlled and pneumatically driven for providing mechanical ventilation in the Operating Room. It comprises of a Control module and a Bellow-in-Jar assembly. The control module has a color LCD screen of size 8.4 inches and resolution of 329 x 600 pixel.

The ventilator is electronically controlled and pneumatically driven for providing mechanical ventilation in the Operating Room. It comprises of a Control module and a Bellow-in-Jar assembly. The control module has a color LCD screen of size 8.4 inches and resolution of 329 x 600 pixel.

It has advanced features that ensure adequate ventilation despite the presence of high machine compliance, changes in lung characteristics or changes in FGF. Its three-stage regulation of tidal volume is noteworthy.

Other advanced features include Pressure Control Ventilation (PCV), Pressure Regulated Volume Control (PRVC) and Pressure Support Ventilation (PSV).

Other advanced features include Pressure Control Ventilation (PCV), Pressure Regulated Volume Control (PRVC) and Pressure Support Ventilation (PSV).

It provides for calibrating the compliance of the entire circle system. it is significant for compensating the tidal volume for loss due to compression of gas.

The anesthesia circle system has a considerable space for compression of gas. Thus, a part of set tidal volume remains compressed in the system itself and is never delivered to patient. This results in hypoventilation and raised EtCO2

To compensate, an amount equivalent to the shortfall is added to the set volume to retain the tidal volume unchanged. To illustrate, if set tidal volume is 400ml and the calculated compressible volume is 100 ml, the unit would process to deliver 500ml instead.

The micro-processor continuously calculates the compressible volume depending the compliance of the entire circle system.

Benefits: The feature is very significant to check against hypoventilation resulting in raised ETCO2, a common occurrence in conventional anesthesia machines.

The actual tidal volume delivered by a mechanical breath also varies with changes in lung characteristics. To nullify this effect, the unit applies ‘Breath-to-Breath’ correction. The process involves monitoring each mechanical breath and providing the appropriate alteration in tidal volume subsequently.

Benefits: Ensures adequate ventilation despite changes in lung characteristics. Ventilating an obese or a patient in prone position is easy to perform.

The tidal volume is also affected by the amount of Fresh Gas Flow. As the flow is mixing continuously into the circle system, a part of it is also added to the delivery throughout the inspiratory time. This results in increased tidal volume.

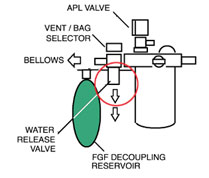

To check against the phenomenon, the unit temporarily shuts the mixing of FGF to the circle system during mechanical breath. Instead, the continuous flow is stored in a reservoir for the period and added back just after the inspiratory phase.

Benefits: The feature makes the tidal volume independent of FGF setting. It is relevant when FGF is changed as a routine.

The unit provides this facility for correct operation of O2 cell as it gets affected by its exposer to oxygen. The cell is kept exposed to atmosphere for a few seconds and the calibration key is pressed to start the process. When the calibration is over, the operator is asked to proceed for his next.

At times pressure controlled mechanical ventilation may be advisable considering the possibility of ‘ventilator induced lung injury’. But it requires operators’ constant attention for repeated adjustment of pressure which is just enough to maintain adequate ventilation.

The PRVC mode does this job of adjustment very efficiently to provide the adequate ventilation at minimum pressure. Starting with lower to higher pressure, sample breaths are generated. Only after a few such sample breaths, the desired minimum pressure is arrived at.

Benefits: Pressure control may be a better option in view of lung injury with volume control. PRVC relieves the operator from the troublesome adjustment of pressure.

As the unit uses inverted bellow for ventilation, certain pressure is required to lift and hold it at the top during expiration phase. That forms the minimum PEEP and is always positive. It is not at zero pressure even if we select PEEP at ‘OFF’ position, an option found in conventional machines using inverted bellows

| Dimension 146 cm x 58 cm x 75 cm |

| Flow Control O2 : 0 -10 LPM, N2O : 0 -12 LPM, Air : 0 -15 LPM |

| Gas inlet 2 pin index yokes for O2 & NO2 3 connectors for pipeline (Air, O2 N2O) |

| Emergency O2 35 to 45 LPM 2 |

| CO Absorber Single jar, capacity 1.5 kg |

| Ventilator display 8.4 inch colour TFT screen |

| Ventilation Modes CMV (VC, PC), PRVC, SIMV (VC, PC) & SPONT |

| Tidal Volume 20 to 1500 ml |

| Frequency 1 to 50 BPM |

| Inspiratory time 0.3 to 3 seconds |

| Inspiratory Hold 3 to 30 cm H2O |

| Electronic PEEP 3 to 30 cm H2O |

| PCV 3 to 40 cm H2O |

| PSV 0 to 30 cm H2O |

| Sensitivity 0.5 to 8 cm H2O |

| Monitored data Tidal Vol, Minute Vol, Peak Pressure, Plateau Pressure, MAP |

| Graph Pressure-Time curve |

| Alarms High / low peak pressure, high / low Tidal Volume, apnea, O2 Fail, high/low FiO2 , source failure |

| Electrical Power 220 VAC, 60 Watt. |